IOP Certification Process

Background to the development of the DMR Interoperability Process

The DMR, Digital Mobile Radio, Association developed the DMR Interoperability (IOP) Process so that users and equipment suppliers benefit from a truly open multi-vendor market for DMR equipment. A competitive, open, multi-vendor market brings proven benefits to users giving choice of equipment and supplier, ongoing development of new products with increased functionality and improved price performance. The open standard gives manufacturers a growing market and eliminates different and incompatible implementations of the DMR standard.

The Interoperability process is a formal and consistent test mechanism allowing manufacturers to test that their products are compatible. One purpose of the DMR IOP Process is to encourage competition; creating a market of multiple and mutually compatible products. Customers can then select the most appropriate products for their needs with confidence that these products are compatible with each other. All products awarded a DMR IOP Certificate have been rigorously tested and the functions listed in the certificate are interoperable. Users can rely on this in selecting equipment from a number of suppliers; this reduces the amount of system integration and testing that they need to do. It also provides the certainty that where a second supplier is added later that existing equipment will not become obsolete.

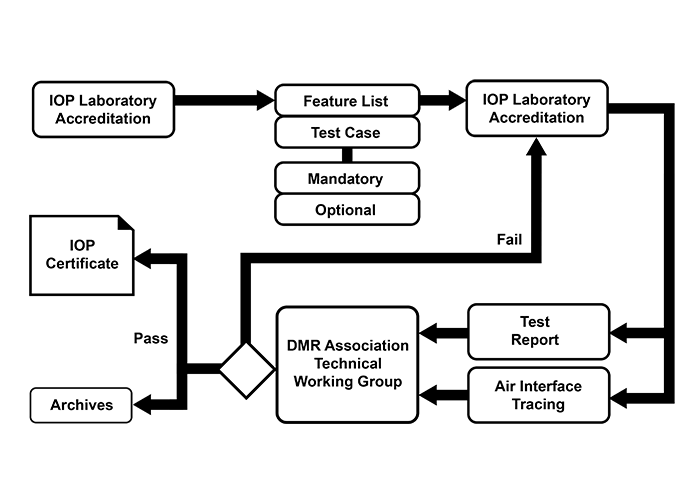

The DMR IOP is managed by the Technical Working Group (TWG) of the DMR Association. The TWG maintains lists of mandatory and optional interoperability features for conventional (Tier II) and trunked (Tier III) DMR based on the published DMR standard. To be certified as interoperable with a second manufacturer for a particular tier, an equipment manufacturer must be interoperable, for that manufacturer, for the mandatory features. Additionally manufacturers can seek IOP certification for optional features by using the defined test process.

The TWG has documented laboratory quality standards and procedures to be met by any laboratory running a test session. Before the test session manufacturers must declare that their laboratory meets the quality standards. For both mandatory and optional features the procedures set out how each test is to be run to demonstrate interoperability and gives test report forms must be completed. During the test process air interface messages is to be captured and stored, as part of the test process. There is also a visual inspection of the air interface logs to confirm there is no conflict with the test results. If both manufacturers agree that interoperability has been demonstrated the test reports and log files are sent to the TWG which presents them to a full TWG meeting for confirmation.

The IOP testing process tells users:

- Both vendors agree interoperability,

- Documented evidence has been made of interoperability at the functional level and from the air interface record,

- The laboratory test site has been set up to industry accepted quality standards,

- Tests are peer reviewed by technically skilled representatives of manufacturers in the industry,

- The test results have been peer reviewed by technically skilled representatives of manufacturers in the industry;

- Testing sessions will be done between two manufacturers. Test sessions and the whole Certification Process will be funded by the two participating manufacturers.

DMR Interoperability Certificates

The results of the functional testing and the air interface logs are analysed and presented in the DMR IOP certificates. This analysis demonstrates that interoperability between manufacturers’ products is subject to a high level of checking. Certificates are hardware platform specific and software release specific.

Products not directly used in a test session but which belong to the same model class, (meaning equipment that manufacturers have determined, through engineering analysis or internal functional testing, to be functionally equivalent to the products tested) may be declared interoperable by manufacturers.

DMR IOP certificates and summary test reports are published on the DMR Association web site. The aim is that certificates are published within 2 months of a test session. The certificates detail which features have been tested, whether interoperability has been achieved and any other relevant details.

Liability Disclaimer

The DMR Association declares that the IOP validation process has been carried out with the best possible endeavours to ensure the most reliable results.

The DMR Association takes no responsibility for, and shall have no liability as a result of damages, losses, or injuries of any kind that may be caused by non-conformance to the functions listed in the certificates by products that are awarded a DMR Interoperability Certificate.

Individual manufacturers are responsible for ensuring that the behaviour of any equipment for which conformance is claimed is identical to that of the equipment that passed the DMR Association interoperability Certification Process.